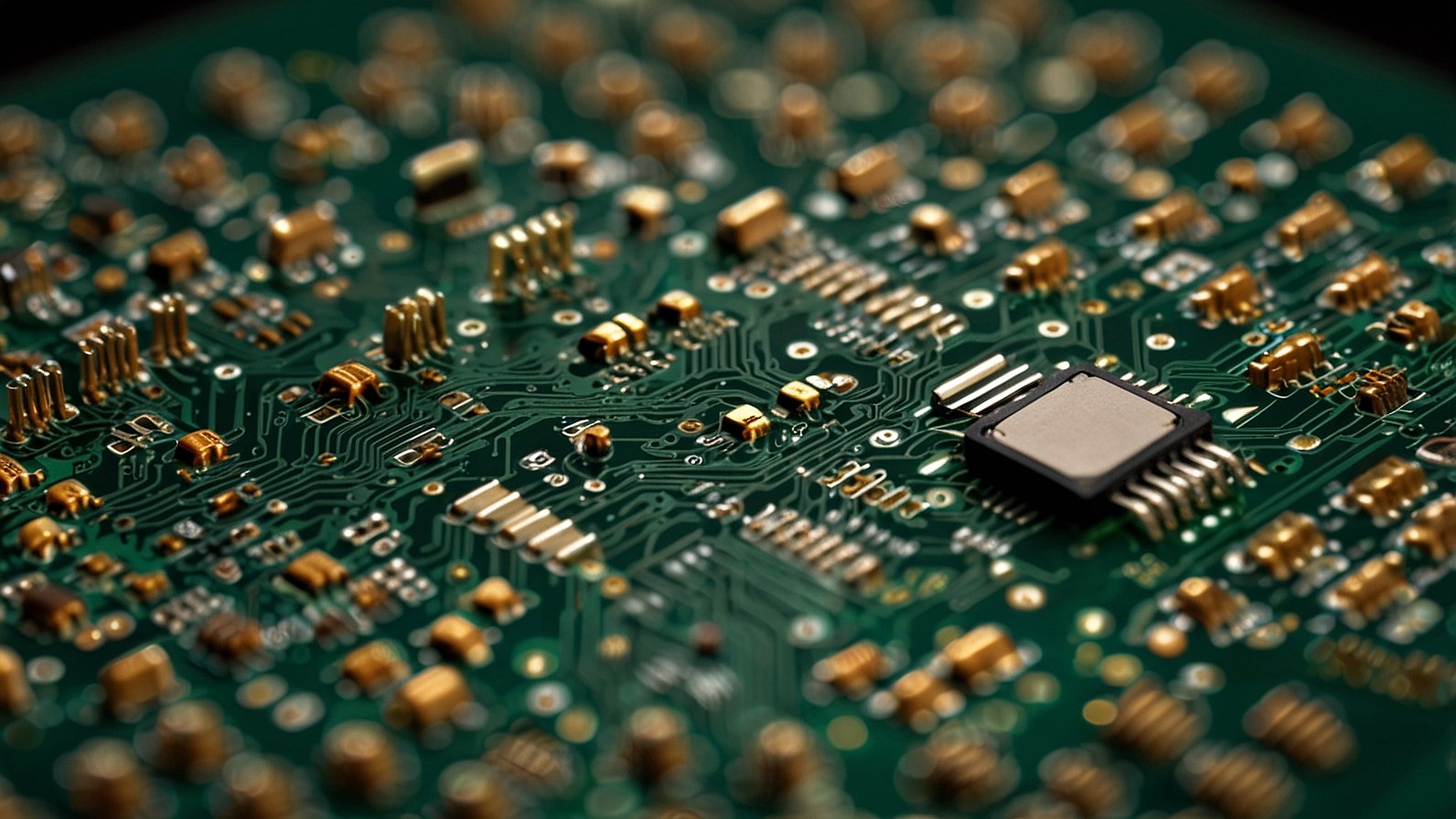

Have you ever excitedly opened a new gadget, only to find a frustrating tangle of wires inside? What transforms that potential mess into a sleek, functional device is often a simple, unassuming component: the PCB header. These tiny, peg-like connectors are the unsung heroes of electronics, providing the critical interface between a circuit board and the wider world. From the robotic arm in a factory to the router powering your home Wi-Fi, PCB headers enable modularity, serviceability, and reliable connections. This article dives into everything you need to know about these fundamental components and how partnering with an expert manufacturer like Global Well PCBA ensures they are integrated perfectly into your printed circuit board assembly.

What Exactly Are PCB Headers?

Think of a PCB header as a sturdy docking port soldered directly onto your circuit board. It’s designed to accept a matching connector—often called a receptacle or socket—that terminates a wire or cable. This creates a secure, removable link. Unlike permanent soldered joints, headers allow for components to be easily installed, upgraded, or replaced. This is why you’ll find them connecting everything from fan cables and sensor modules on a motherboard to the intricate subsystems within an industrial control panel.

The core advantage is modularity. This design philosophy saves time during assembly, simplifies repairs, and future-proofs your product. For a PCBA manufacturer, precision in placing and soldering these headers is paramount, as misalignment can lead to connection failures or damage.

A Guide to Common PCB Header Types

Not all headers are created equal. Choosing the right type is crucial for the electrical and mechanical demands of your application. Here’s a breakdown of the most common varieties you’ll encounter.

Pin Headers: The Universal Standard

These are the most recognizable type, consisting of a single or double row of metal pins molded into a plastic base. They are incredibly versatile.

- Single-Row (SIP): Often used for simpler board-to-board connections or jumpers.

- Double-Row (DIP): Provide higher density for more complex interfaces, like connecting to an LCD screen.

- Mounting Style: They can be straight (vertical) or right-angle, offering flexibility in how a connected cable exits the board, which is vital for managing space within an enclosure.

Box Headers: The Secure Choice

Imagine a pin header where each pin is surrounded by a protective shroud. That’s a box header. This design offers superior protection against physical damage and better guides the mating connector for a foolproof connection. They are the go-to for industrial and automotive applications where vibration and mishandling are concerns.

Female Headers & Sockets

While “PCB header” often refers to the male pin version, the female counterpart is equally important. These sockets are soldered onto the PCB and accept bare pins from another board or component. They are essential for creating stackable board configurations, like in a Raspberry Pi HAT add-on board.

Specialized Headers for Advanced Applications

This is where technical expertise truly shines. At Global Well PCBA, we regularly work with sophisticated headers for advanced PCB solutions:

- For High-Frequency PCBs: In telecommunications and RF applications, impedance-matched headers (like SMA, U.FL) are critical. They preserve signal integrity by minimizing reflection and loss at GHz frequencies.

- For Rigid-Flex PCBs: Headers used in these dynamic structures must withstand repeated flexing without cracking solder joints. Strain-relief and low-profile designs are often specified.

- High-Current Headers: In power electronics and robotics, headers with thicker pins and higher-temperature materials are used to safely carry significant current without overheating.

Quick Reference Guide to PCB Header Selection

| Header Type | Best For | Key Consideration |

|---|---|---|

| Standard Pin Header | General I/O, jumper connections, prototyping | Pin spacing (pitch), row count, straight vs. right-angle |

| Box Header | Industrial controls, automotive, harsh environments | Mating security, physical durability |

| Female Socket | Board stacking, modular add-ons | Retention mechanism (friction-lock, latching) |

| RF/Coaxial Header | Telecom, RF modules, antennas | Impedance rating (e.g., 50Ω), frequency range |

| Power Header | Motor drives, power supplies, robotics | Current rating, pin thickness, insulation material |

Why Correct Header Integration Matters in PCBA

Soldering a header seems simple, but in high-volume or high-reliability production, the devil is in the details. Incorrect handling can lead to a cascade of problems.

Common Pitfalls and How to Avoid Them:

- Tombstoning: During reflow soldering, one end of a header can lift off the pad, leaving the component standing upright like a tombstone. This is caused by uneven thermal mass or pad design. Our engineering team optimizes the PCB footprint and thermal profile to prevent this.

- Poor Solder Fill: Headers with through-hole pins require complete solder fill in the plated holes for mechanical strength. Insufficient solder can create a weak joint that fails under stress.

- Misalignment: Even a slight angle in placement can make mating the connector difficult or impossible. We utilize advanced optical placement systems and strict quality control checks to ensure perfect alignment every time.

The Global Well PCBA Advantage: Our expertise isn’t just in placing components. We provide Design for Manufacturability (DFM) feedback early in your process. We might advise on optimal header placement for automated assembly, recommend a more suitable pitch for your current needs, or suggest a shrouded variant for a robotics application subject to constant movement. This proactive collaboration turns a good design into a manufacturable, reliable product.

PCB Headers in Action: Real-World Applications

Let’s move beyond theory and see how these connectors enable innovation across industries.

In Robotics and Automation: A single collaborative robot arm is a symphony of interconnected systems. PCB headers link motor drivers to the main control board, connect force sensors, and interface with tool changers. The ability to quickly disconnect a faulty sensor module minimizes downtime, keeping production lines moving. The robustness required here directly informs our material and process choices at Global Well PCBA.

In Telecommunications Infrastructure: Inside a 5G baseband unit, High-Frequency PCBs are studded with specialized RF headers. These connectors must maintain signal purity in a crowded, high-speed environment. Any mismatch or loss at these connection points can degrade network performance. Our experience with high-frequency materials like Rogers or Taconic ensures these critical interfaces are implemented flawlessly.

In Consumer Electronics: The push for thinner, sleeker devices has driven the adoption of ultra-low-profile and board-to-board headers. These allow for complex, multi-board arrangements in smartphones and tablets. The precision required for these tiny-pitch connectors (0.4mm or less) highlights the need for a manufacturer with cutting-edge SMT equipment and inspection capabilities.

3 Actionable Tips for Your Next Design

- Plan for Serviceability First. Always ask: “Will this need to be disconnected for testing, repair, or upgrade?” If yes, a header is your friend. It adds minimal cost but immense value over the product’s lifecycle.

- Consult Your PCBA Partner Early. Don’t finalize your BOM (Bill of Materials) in a vacuum. Share your design with your manufacturer. We can advise on header availability, cost-effective alternatives, and layout optimizations to prevent assembly headaches.

- Test the Mating Cycle. For critical connections, specify headers rated for enough mating cycles (often 50, 100, or more). A $0.10 part failing after 20 connections can cost thousands in field repairs. We can help source components that match your durability requirements.

PCB headers may be small, but their role is monumental. They are the handshake between your brilliant circuit design and the real world. Choosing the right type and ensuring its perfect integration requires a blend of thoughtful design and manufacturing excellence.

At Global Well PCBA, we combine advanced technical expertise in Rigid-Flex, High Frequency PCBs, and complex assembly with a practical, collaborative approach. Let’s connect your next big idea. Share your thoughts or questions about your specific project in the comments below!

FAQs

What’s the difference between a header and a connector?

The terms are often used interchangeably, but technically, the header is usually the male portion (pins) soldered to the PCB. The connector often refers to the mating female part (socket) attached to a wire or cable. Together, they form a connector system.

What does “pitch” mean in a PCB header?

Pitch is the center-to-center distance between adjacent pins, most commonly 2.54mm (0.1 inches) for standard headers, and as small as 0.5mm for fine-pitch designs. Choosing the correct pitch is essential for mating compatibility and manufacturability.

Are pin headers reusable?

Yes, they are designed for multiple mating and unmating cycles. However, the lifespan depends on the quality of the header and its mating counterpart. Always check the manufacturer’s rated mating cycle specification for critical applications.

Can Global Well PCBA help source and procure the correct headers?

Absolutely. As a full-service PCBA manufacturer, we offer component sourcing as part of our service. We leverage our supply chain relationships to procure quality, cost-effective headers and manage the entire BOM, reducing your logistical burden.

How do you ensure headers are soldered correctly during mass production?

We use a combination of precision SMT machines for surface-mount headers and selective soldering or wave soldering for through-hole types. Every board then passes through automated optical inspection (AOI) and X-ray inspection (for hidden joints) to verify perfect solder formation and alignment.

What are the challenges with very fine-pitch headers?

Fine-pitch headers (below 0.8mm) require extremely accurate PCB fabrication, solder paste stenciling, and component placement. Solder bridging between pins is a common risk. Our state-of-the-art assembly lines and SPI (Solder Paste Inspection) processes are calibrated to handle these challenges reliably.

Are there waterproof PCB headers?

Yes, for outdoor or harsh environment applications (like automotive or marine electronics), IP-rated waterproof headers with sealing gaskets are available. It’s crucial to specify this requirement early so we can advise on suitable parts and board layout considerations.

You May Also Like: Demystifying Tech: Your Friendly Guide to Tech TheBoringMagazine